It is a comprehensive enterprise integrating yarn production (ATY), weaving and trading.

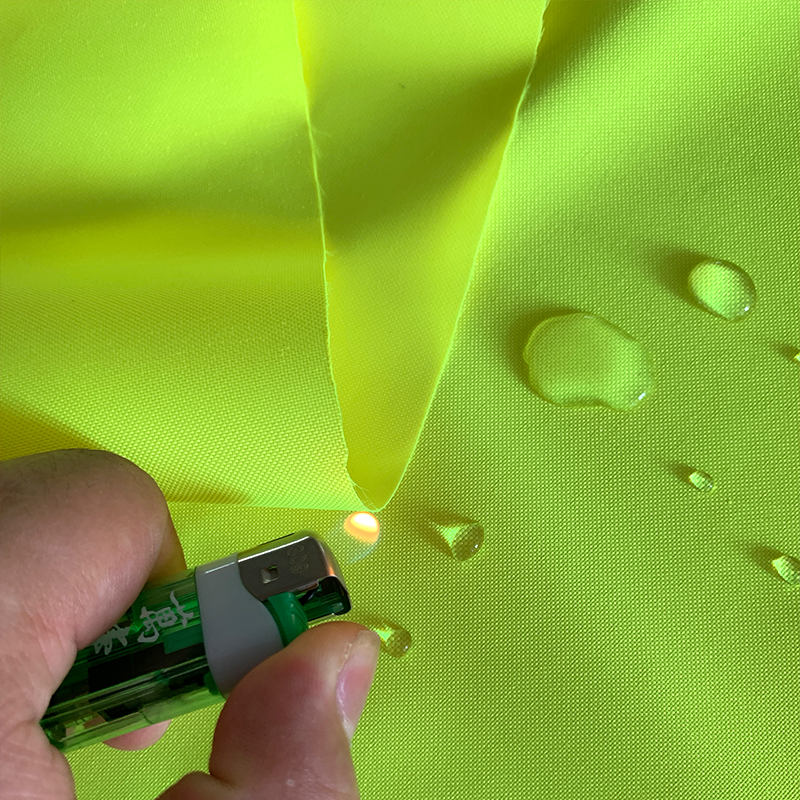

The specific flame retardant properties of blackout fabric can vary depending on the manufacturing process, the type of flame retardant used, and compliance with industry standards. Here are some common flame retardant properties that blackout fabrics may possess:

Chemical Flame Retardants:

Flame retardant (FR) blackout fabrics often incorporate chemical additives that suppress or inhibit the spread of flames.

Phosphorus-based, nitrogen-based, or halogen-based flame retardants are commonly used in textiles.

Self-Extinguishing:

Flame retardant blackout fabrics are designed to be self-extinguishing, meaning they resist continued burning once the ignition source is removed.

Low Flame Spread:

The fabric is engineered to have a low flame spread rate, preventing the rapid spread of fire across its surface.

Compliance with Standards:

FR blackout fabrics should comply with relevant safety standards and regulations for flame resistance in textiles.

Standards may vary by region, but common ones include NFPA 701 in the United States and BS 5867 in the United Kingdom.

Ignition Resistance:

The fabric is resistant to ignition, reducing the likelihood of catching fire when exposed to an open flame.

Heat Resistance:

FR blackout fabrics are designed to withstand exposure to heat without igniting or sustaining combustion.

Smoke and Toxic Gas Emission:

These fabrics aim to minimize the release of smoke and toxic gases in the event of a fire, contributing to improved fire safety.

Durability of Flame Retardant Treatment:

The flame retardant treatment is designed to be durable, maintaining its effectiveness over the lifespan of the fabric.

It should withstand regular use, cleaning, and exposure to environmental factors.

Resistance to Fire-Related Hazards:

FR blackout fabrics should resist the development of fire-related hazards, such as melting or dripping, which could contribute to the spread of flames.

Environmental Considerations:

Some flame retardants used in blackout fabrics may raise environmental concerns. Manufacturers may offer options with environmentally friendly flame retardants.

It's important for consumers and specifiers to check the product specifications and documentation provided by the manufacturer to understand the specific flame retardant properties of the blackout fabric. Compliance with relevant safety standards and certifications is a key indicator of a fabric's flame resistance. Additionally, following proper care and maintenance instructions is essential to preserve the effectiveness of the flame retardant treatment over time.

English

English 中文简体

中文简体

.jpg?imageView2/2/format/jp2)