It is a comprehensive enterprise integrating yarn production (ATY), weaving and trading.

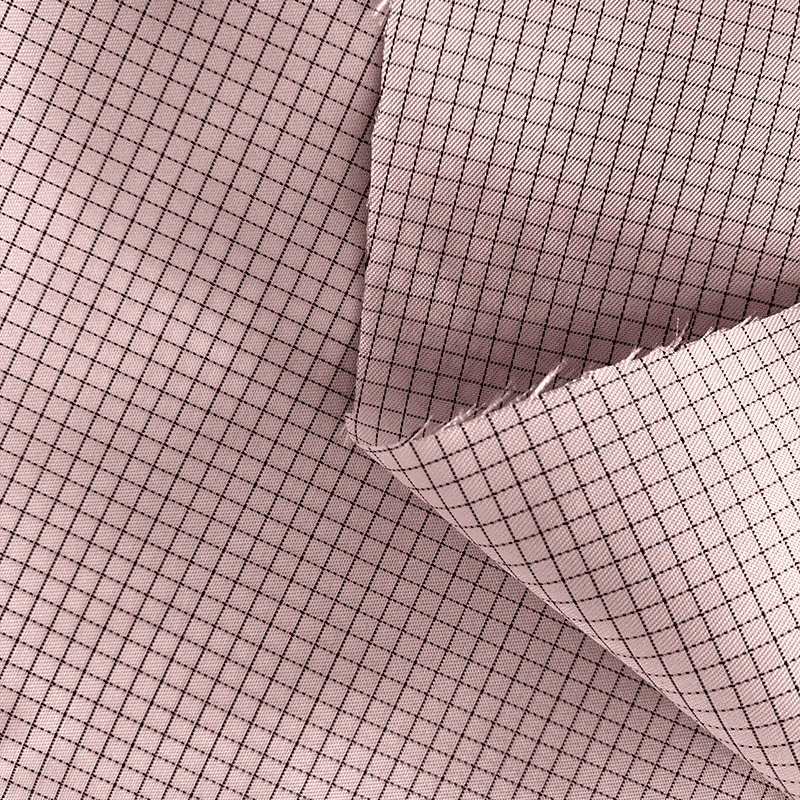

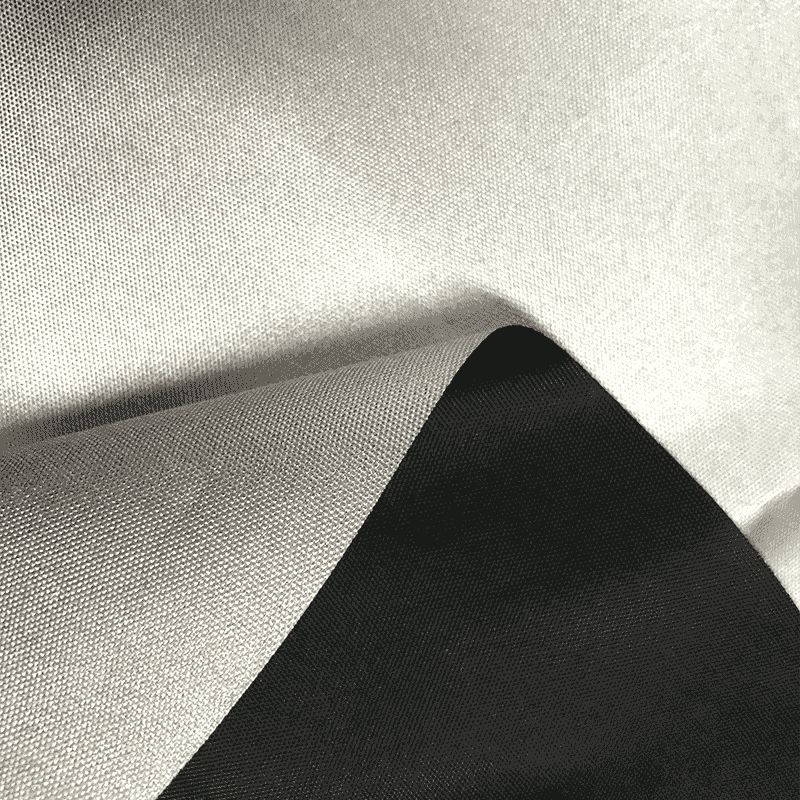

Antistatic fabrics are designed to reduce or eliminate the buildup of static electricity, which can be particularly useful in environments where static discharge could damage sensitive electronic equipment or pose safety risks. The breathability of antistatic fabrics depends on various factors, including the specific type of fabric, its construction, and any additional treatments applied.

In general, the breathability of antistatic fabrics can vary, and it may not be as high as that of some natural fibers like cotton or linen. Here are a few considerations:

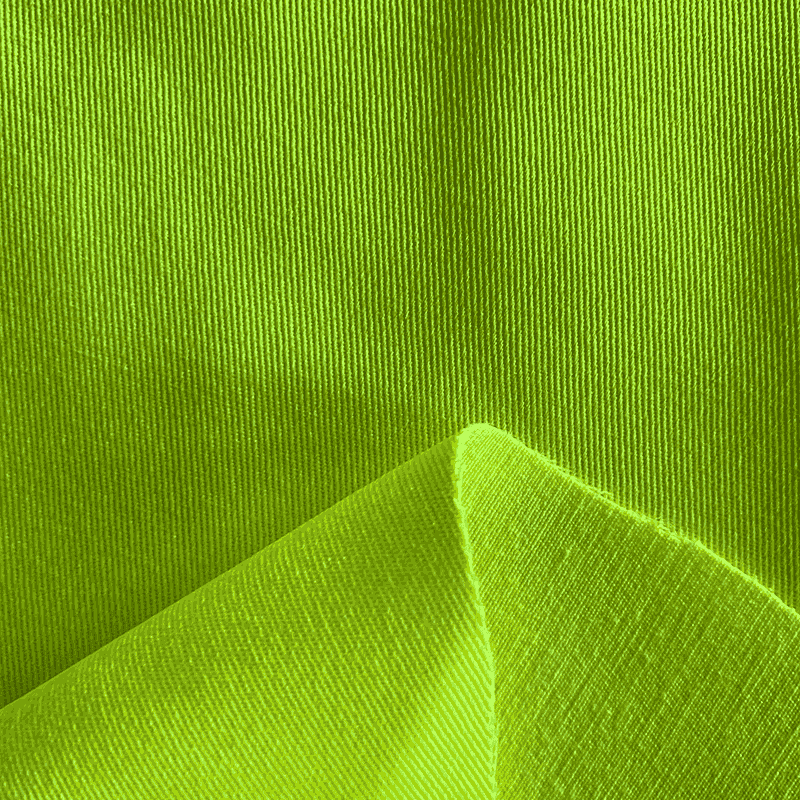

Material Type:

The base material of the antistatic fabric plays a role in its breathability. Common materials used for antistatic fabrics include synthetic fibers like polyester or a blend of synthetic fibers.

Weave and Construction:

The weave and construction of the fabric can impact its breathability. Some tightly woven fabrics, common in antistatic materials, may have reduced breathability compared to more open weaves.

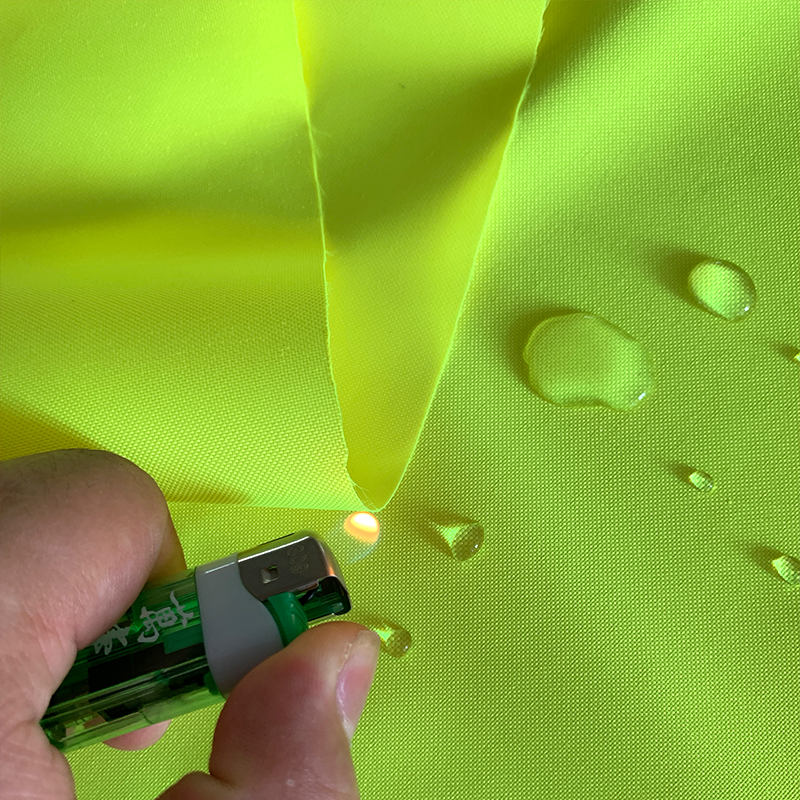

Additional Coatings or Treatments:

Some antistatic fabrics may have coatings or treatments applied to enhance their antistatic properties. These treatments may affect the breathability of the fabric.

Design and Application:

The design and intended application of the antistatic fabric can influence its breathability. For example, antistatic clothing designed for use in cleanroom environments may prioritize static control over breathability.

While antistatic fabrics may not always be as breathable as certain natural fibers, advancements in fabric technology have led to the development of antistatic materials with improved breathability. Manufacturers may incorporate features such as moisture-wicking properties or engineered ventilation to enhance comfort.

If breathability is a critical factor for your specific application, it's essential to check the specifications provided by the manufacturer and, if possible, request samples to assess the fabric's feel and comfort. Additionally, considering the specific needs of the environment where the antistatic fabric will be used is crucial in determining the effectiveness of both antistatic properties and breathability.

English

English 中文简体

中文简体

.jpg?imageView2/2/format/jp2)