It is a comprehensive enterprise integrating yarn production (ATY), weaving and trading.

The range of applications and end uses of air-deformed yarns are usually determined by their structure and properties. Due to these versatility of the air-deformation process and its yarns mentioned earlier, air-deformed yarns can be used in all areas of the textile industry.

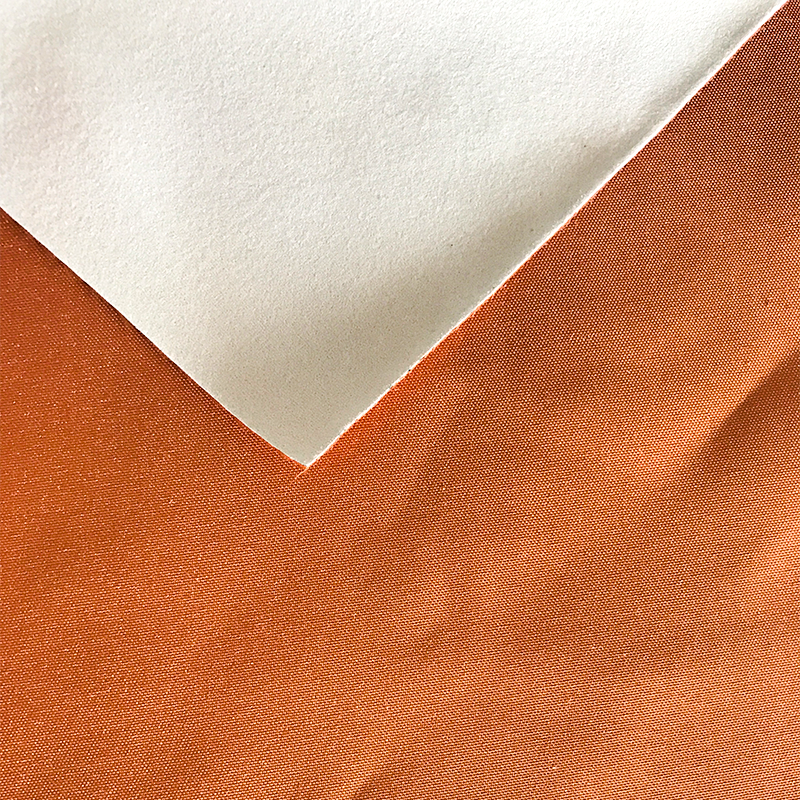

Nylon air-deformed yarns for woven fabrics

Nylon air-deformed yarns for skiwear are the first market for air-deformed yarns as weft yarns for weaving. Due to the adhesion of the filament loops on the surface of the adjacent yarns to each other, it was difficult to rewind them and they could not be used as warp yarns without sizing or twisting. Nowadays, these limitations no longer exist, for example, by using fine denier yarns, or by combining different filaments.

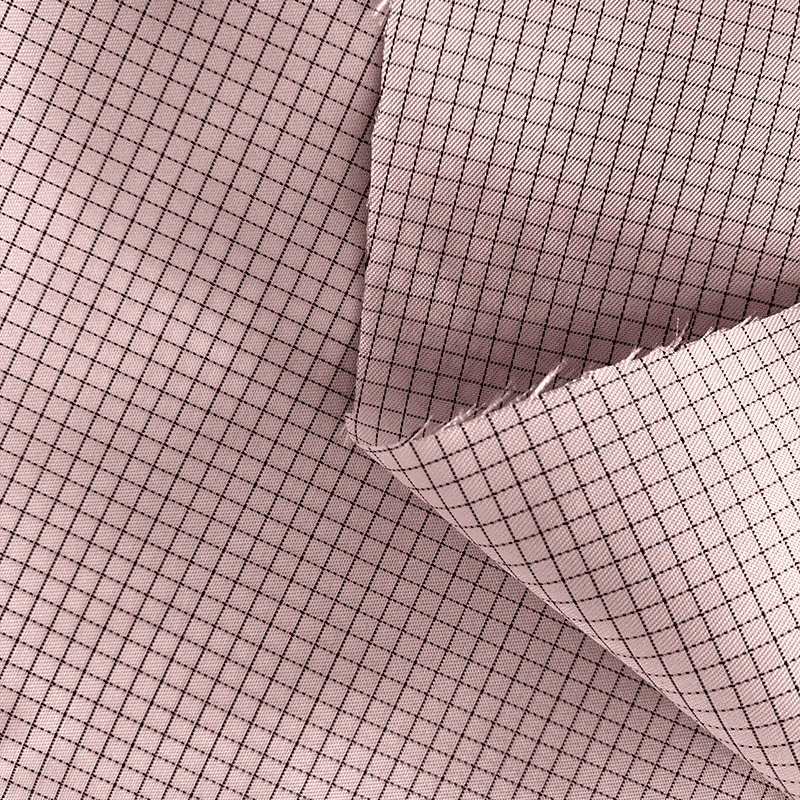

Polyester air-variable yarns for automotive applications

For automotive interiors, seat covers, seat backs, inner door panels and inner roof panels can be made from polyester voile yarns. Automotive seats are often exposed to heat, strong sunlight and a lot of wear and tear. Polyester air-deformed yarns can meet these requirements.

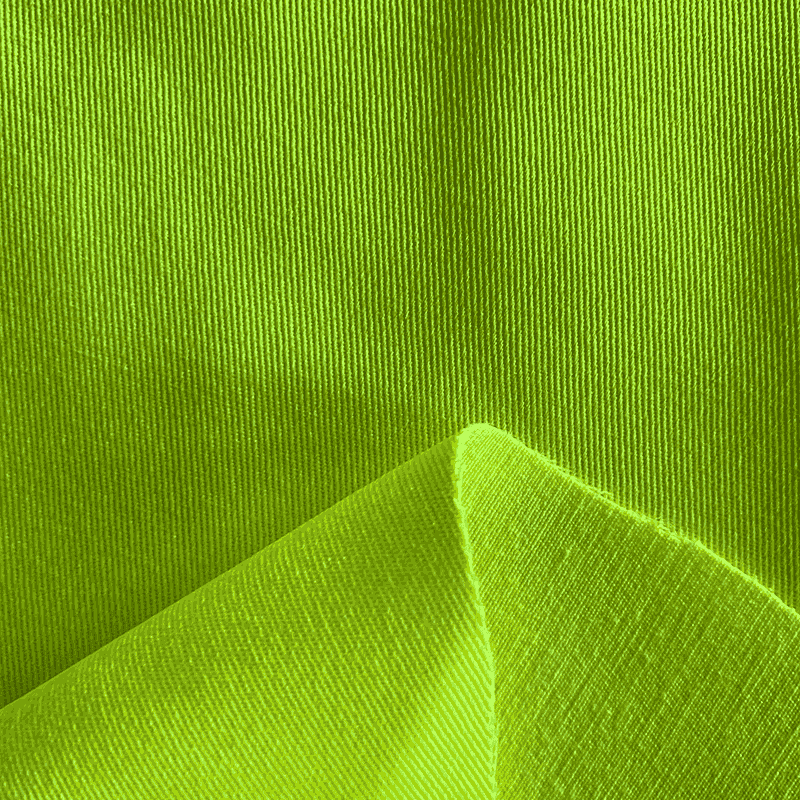

Polypropylene air-deformed yarns for decorative fabrics

Most air-deformed yarns for decorative materials are made by the spinning-drafting process, so they do not need to be drafted before being deformed. Several yarns can be placed on the cylinder frame at the same time, e.g. 5 or 6 single yarns, so a single yarn breakage or defect detection device is necessary. The feed yarn is usually a melt dyed yarn.

For decorative fabrics, polypropylene yarn with a density of 4.4~6.7 dtex is used, and due to the high overfeeding rate of the skin yarn, linting or hooking can easily occur. Therefore it is advisable to use conical cylinder winding.

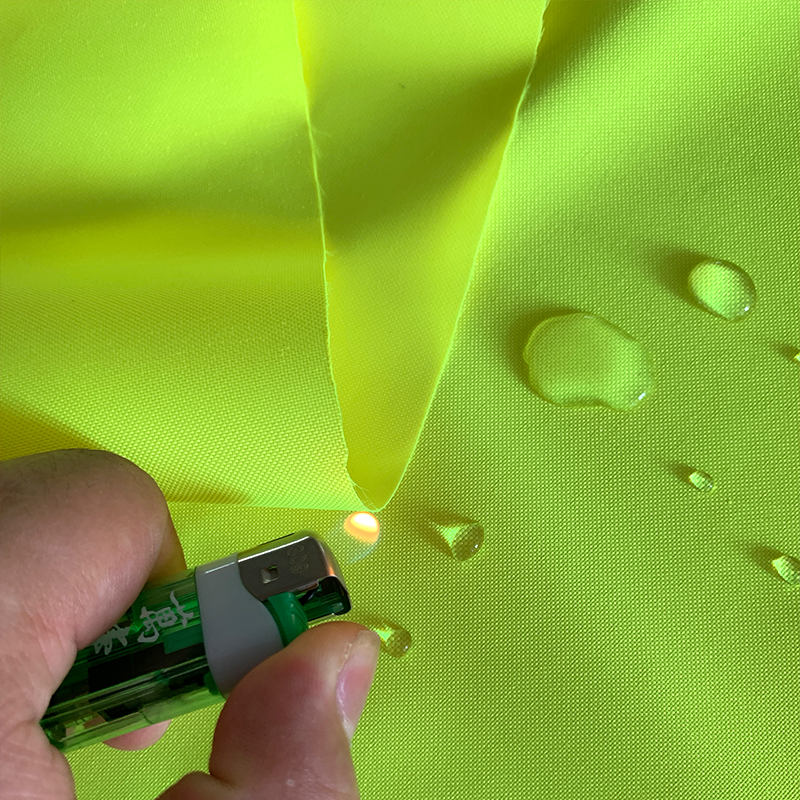

Polyester air-change yarn suitable for sewing thread

One of the very special applications of polyester air-deformed yarns is for sewing threads. Air-deformed yarns not only have high tensile strength, but also excellent abrasion resistance. Due to the surface arc structure of air-deformed yarns, sewing threads can be processed at speeds higher than 6000 stitches/min without melting or breakage.

English

English 中文简体

中文简体

.jpg?imageView2/2/format/jp2)